An inspector can simply drag their fingernail from the inside of the cup out to the outer edge and if a J-hook is present, his or her nail will catch on the hook. If the J-hook is light, it can be removed by polishing. In addition, polishing restores the cup’s mirror luster

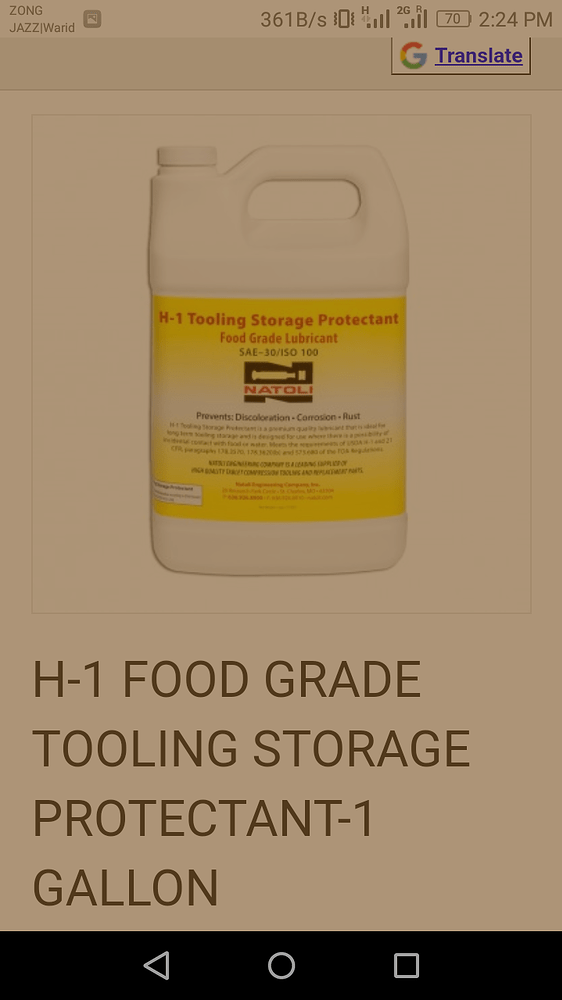

Can plz named some branded lubricants which can be used before storage of Punches

Thanx

well come

what is Automated polishing? how to perform?

its auto polishing machine

what kind of preservative/lubricant is used ?

@saifulnsu

for storage

I want to know the name of presevative / lubricant

- 21.CFR 178.3570 – Allowed ingredients for the manufacture of H1 lubricants

- 21.CFR 178.3620 – White mineral oil as a component of non-food articles intended for use in contact with food

- 21.CFR 172.878 – USP mineral oil for direct contact with food

- 21 CFR 172.882 – Synthetic isoparaffinic hydrocarbons

- 21.CFR 182 – Substances generally recognized as safe

How to determine life cycle of die and punch?

It can be valitated by observing number of batches compresed on a tooling.

Is there any specific sign that help me to understand ?

yes there may be variation in punch length.

Punch edges may b damagef.

punch tip surface may be eruded.

tab compressed may have a large coller.

increased weiht variation,diff in thickness etc

What is maximum allowable load on punches during compression?

It depend upon hardness required and type of tooling B type or D type

Good reference provided…

Thanks

Which guidelines should I read for Aseptic products