Sifting and blending method we done. For one project but when we compressed the blend we observed tablet hardness issues. For the first Precompression tablet hardness is reached as per BMR hardness limit after that in main compression and precompression also we are unable to reach hardness ?

is there any problem related to powder flow or weight variation?

What kind of binder u r using in ur formulation

No weight variation and good flow properties

Calcium carbonate phosphate binder

try to make slugs.

It’s not a slugging method,we can’t proposed to slugging method

There have a any option to increase hardness

u r not using wet granulation method?

u r using simple mixing(Direct compression method)

If using direct compression then use spray dried lactose n avicel 102 type exceptients.

if no option to change excipients then make machine adjustments.

reduce speed

machine speed and tools penetration and all we done but no results

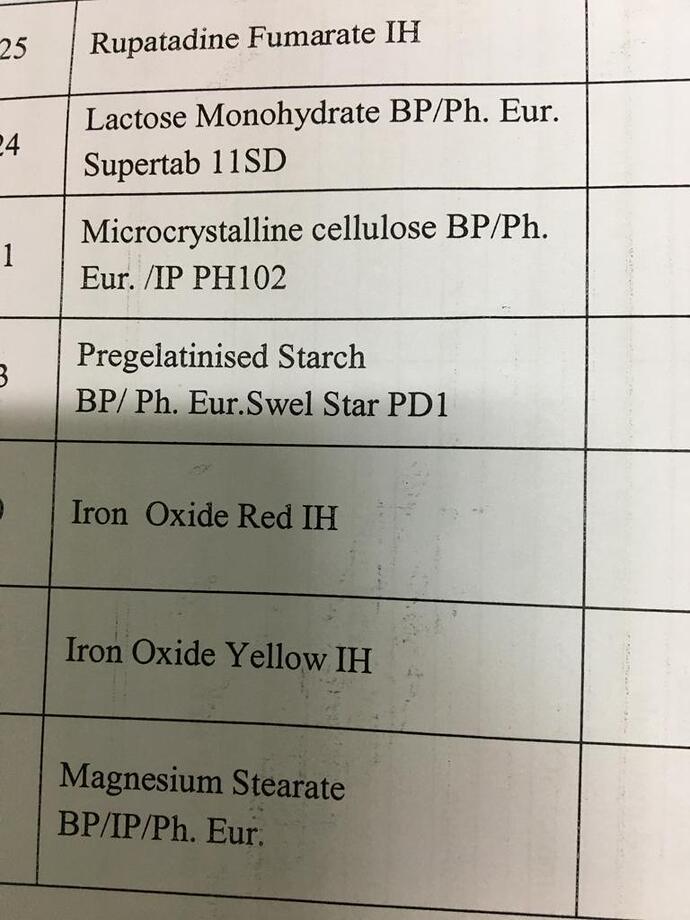

can u share formulation?

If it’s regular commercial batch, this type of reprocessing need management approval… ideally not allowed…

Thanks

batch will be on trouble shoting by product development.

Ya but I want know what is the issue in this

kindly share excepients?

check by increasing qty of MCC

102