In LVP pharmaguideline mentioned autoclave at 108°c for 60 mint.

How to calculate autoclave cycle time 60 mint at 108°c…

Please reply with solution

How to find f0 value…

F0 resulting of a cycle kept at 108°C for 60 min is 3 min. Farely short compared to the 15 min of a tipycal overkill cycle kept at 121°C for 15 min.

Target F0 is calculated based on bioburden (population and resistance) and the sterility level you want to achieve (or at least the log reduction); thus, the 60 min can result of an infinite combination of these terms, not just a single set of parameter values.

So how to chose these values? First, consder that some parenterals where a sterilization temperature of 121°C is not feasable due to product or material degradation; you can lower the sterilization temperature at the cost of incrementing the sterilization time. That way, you expose the product at a reduced (safe) temperature but you keep it long enough to get the same target F0.

Also, you can use a product-specific approach, instead of an overkill approach, by monitoring and controling native bioburden (population and resistance) and establish a reduced combination of D value and population, which results in a lower F0 target value, allowing you to use a lower temperature and avoiding extremely long cycles.

Hope this helps.

How to calculate time 60 mint at 108°c… any formula… and give me example at 108°c for 60 mint.

A quick search within this site showed this page contaning the formula for lethality calculation (F0): https://www.pharmaguideline.com/2011/03/d-value-z-value-and-f0-value.html

As I said, you have to define what is the lethality value (F0) you want to achieve to then ask the quesetion:

What exposure time at 108°C is needed to achieve an F0 value of ______?

If you put 60 min in the formula and solve for F0, the resulting F0 is 3 min.

On a side note, an F0 of 3 min is very low and would require great evidence to support that your process is robust enough to control bioburden (combination of resistance and population) at very low levels.

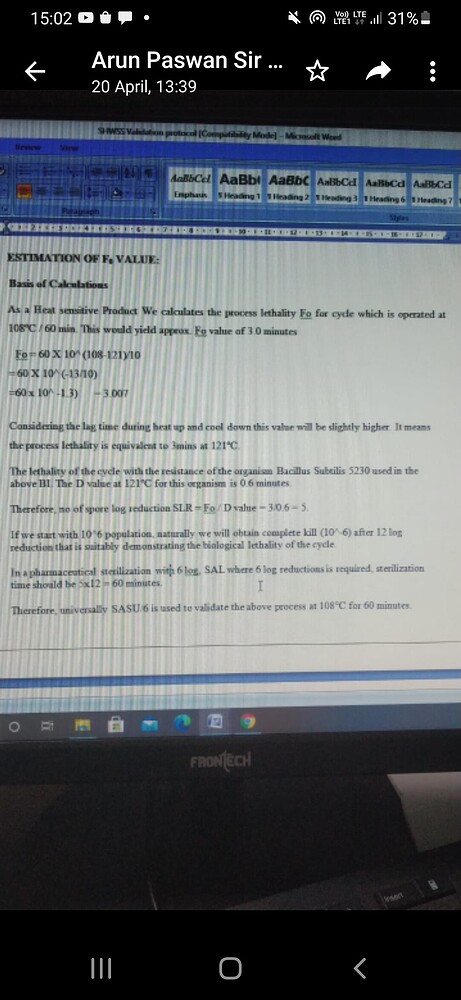

Ok I calculate and got f0 3 mint. But after that what procedure do to get time 60 minutes. Can u attached a calculation file here. where clearly understand time 60 mint at 108°c

-

First, define the lethality level (F0) you need to achieve using this formula:

F0 = D121 * (logN0 - logN)

For the sake of this example we use F0 = 3 min to get 60min at 108°C as a result, later on. -

Then, calcualte the lethality rate at which you can accumulate F0 at 108°C. Use this formula:

L = 10 ^ [ ( T - Tref) / Z ] . . . . You’ll get ≈ 0.05.

This is the amount of lethality you can gain every minute you expose your product at 108°C. -

Then, you just simply divide F0 by L and the resulting time is 60 min.

Now, this is strictly time at 108°C, but consider temperature variations during the process to define final cycle parameters. Also, as I said, F0 of 3 min is very low, consider having a robust control of bioburden to be able to demonstrate to regulatory entities.

I understood sir… thank u… but one question is if I reduce the temperature of autoclave e.g 108°c how to calculate time… I don’t know time for compelete sterilization…

I’m sorry, perhaps I’m not understanding the question.

Step 3 in the previous reply is the step to calulate sterilization time. A bit more detailed here:

In that example, you want to achieve an F0 of 3 min using a sterilization temperature of 108°C.

The formula is this:

Time = F0 / L = (3 min) / (0.05) = 60 min

Sorry, I have trouble understanding the question, I hope this answers it.

My question is that How to calculate autoclave time at 108°c… u put the value 60 mint to determine F0 Value… but how to u know prior must be 60 mint to determine f0 value

No, what I did was calculate the F0 value that you would get IF you sterilize at 108°C for 60 min, since that was the data given by your question; but then I explained why you can’t calculate the time before knowing the level of lethality (F0) you want to achieve and the temperature at which you can sterilize the product.

Your target F0 value is calculated using this formula (no time required):

F0 = D121 * (logN0 - logN)

(Biological approach)

Then you calcualte time using these equations:

L = 10 ^ [ ( T - Tref) / Z ]

time = F0 / L

(Physical approach)

I hope this clarifies my answer

Is this right sir… please reply me

I strongly suggest that the rationale to determine the F0 value comes from a biological and regulatory approach, instead of a physical approach, using this formula:

F0 = D121 * (logN0 - logN)

Since an SAL of 10^-6 is a regulatory requirement, the formula can be written as this:

F0 = D121 * (logN0 - logSAL) = D121 * (logN0 + 6)

Then you need data to define the values of D121 and N0; these should come from a bioburden study that tells you the worst case bioburden count (N0) and resistance (D121) in your product.

Since yout cannot use an overkill approach (F0 of at least 12 min), F0 value depends on the bioburden you want to sterilize; thus, you need a study to measure it.

Once you have that F0, you can then calculate the equivalent time at 108°C as indiacted in previous posts.

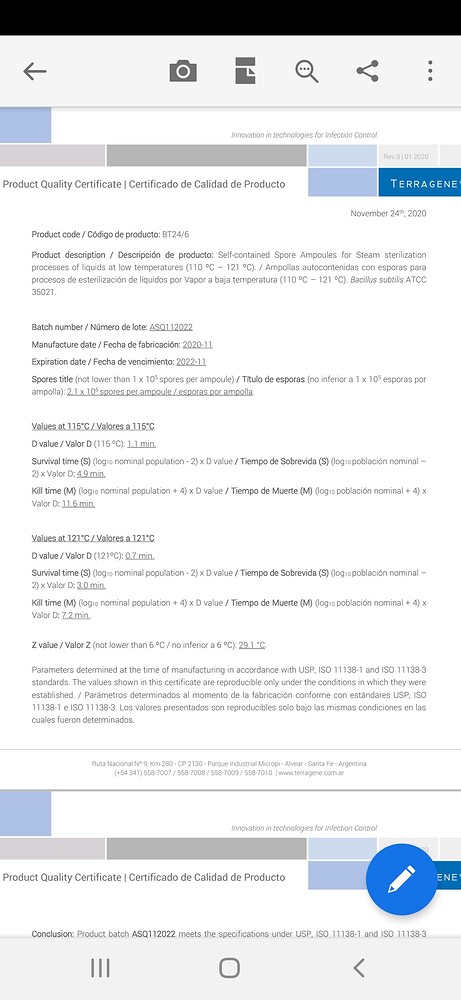

Using BI ( Low Heat BI ) COA

BI lot NO: XXXXXXXX

For example

T1=115 - D115=1.7

T2=118 - D118=1.1

T3=121 - D121=0.7

T4=108 - D108=???

Z value=16.8

Population=2.6 X10^6

D108=D value T2|X10^(T1-T4)/Z

D108=(D115=1.7)X10^(115-108)/16.8

D108=1.7X10^ (0.4166666667)

D108=1.7X2.610157216

D108=4.437267267 min

Kill Time=D-Val [(Log of population+ Factor=4)]

D-Val=4.437267267

Population=2.6 X10^6

Kill Time=4.437 X 10.415

total time = 46.21

You can calculate any other Heat treatment temp ( 106 C or even 102 C)

Please calculate the time at 108°c as per bi certificate

This topic was automatically closed 10 days after the last reply. New replies are no longer allowed.